Maximum lubrication with minimum consumption

W&H Reprocessing Devices

Maintenance devices are indispensable when it comes to ensuring dental transmission instruments work properly, maintain their value, and have a long service life. The W&H Assistina Twin and Assistina One impress with their thorough and comprehensive lubrication of the gear parts and cleaning of the spray channels, as well as their environmentally friendly Care Set.

The Assistina Twin from W&H is unique among maintenance devices with its innovative dual-chamber system and record-time lubrication. The Assistina One is geared towards the needs of users in dental practices and was designed to further simplify the maintenance process and make it more efficient.

Both devices use an innovative nebulisation technique: Finely atomised oil loosens and removes contamination from the internal gear parts under high pressure, without setting them in motion. “Automatic lubrication via Assistina ensures the proper lubrication of handpieces with the correct amount of oil. In addition, unlike manual lubrication, it offers the possibility of cleaning the spray channel. The correct amount of oil guarantees not only the perfect maintenance of transmission instruments but also reduces possible damage to other devices, such as sterilizers, caused by excess oil. Finally, an excess of oil can create spots on pouches after sterilization, potentially affecting sterilization retention”, explains Alberto Borghi the advantages of reprocessing with W&H devices.

The one and only oil

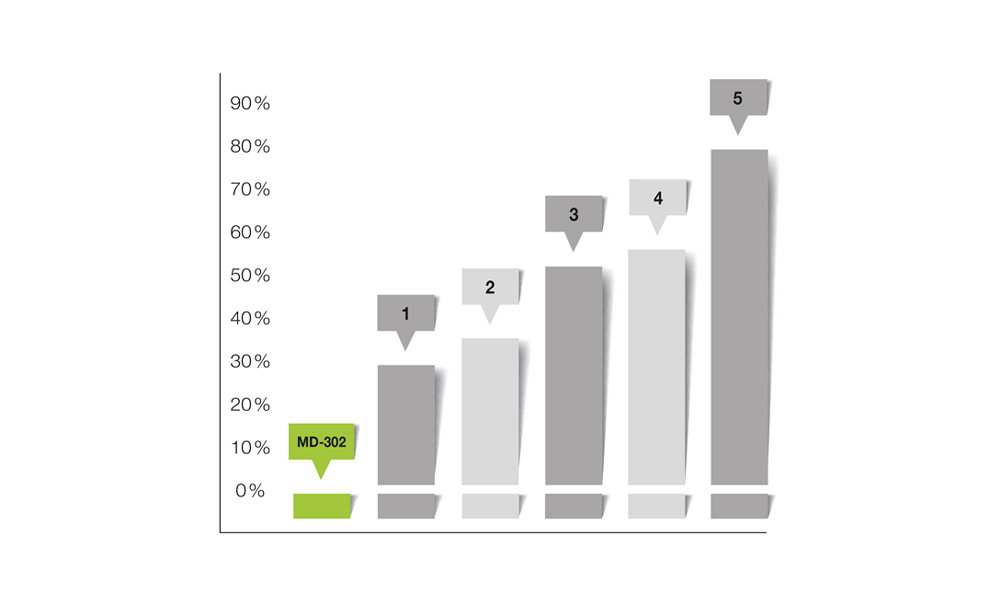

Laboratory tests on oils showed that the Assistina Care Set oil MD-302 leads to a reduced friction rate and significantly lower abrasion of the gear parts compared to the most common competitor products. The abrasion of the gear parts can be reduced from 28% up to 77%. The use of W&H reprocessing devices can therefore lead to resource conservation, given that the handpieces demonstrate prolonged service life and sustain their value over time.

Environmentally friendly and sustainable

The Assistina Care Set oil yields as much as 20 oil spray cans MD-400. Thus, more than 2,800 transmission instruments can be maintained. The W&H reprocessing devices automatically dispense the exact amount of W&H Service Oil and W&H Activefluid needed. Made in Austria with durable, high-quality materials, they also have a small ecological footprint of production. All these features make W&H reprocessing devices a highly economical solution, enabling dentists to save money, time, and waste. “Both Assistina One and Twin pay off their investment within a year due to the fact that their consumables cost less than oil cans. We recommend considering your clinic size when choosing, and in just one year, the Assistina proves to be the financially savvy alternative”, explains Alberto Borghi, W&H product manager for sterilization, hygiene, and maintenance.

kommentarer